Engineered

for excellence.

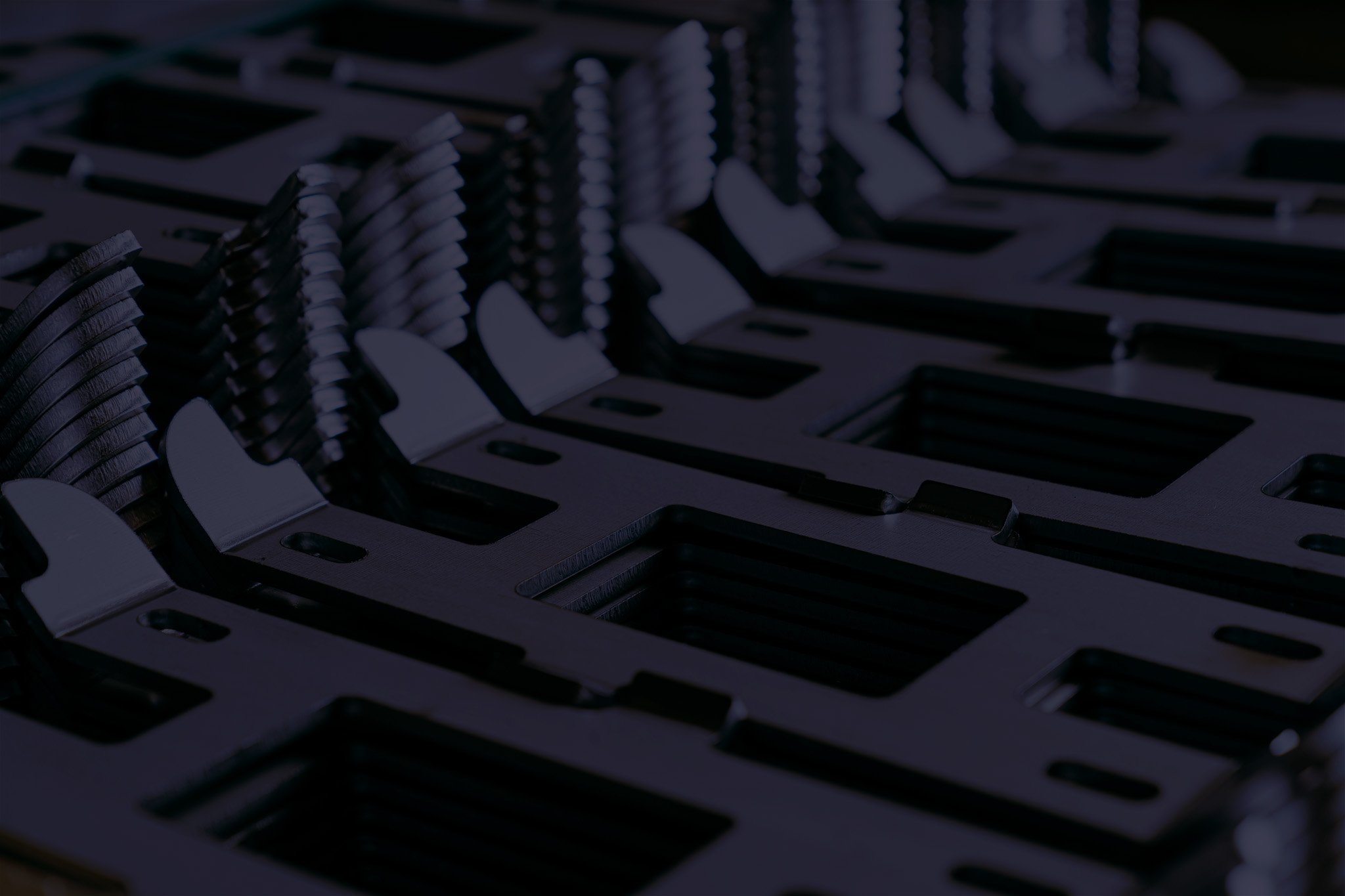

Thermoforming

In thermoforming a plastic sheet is initially heated until it can be formed. When the forming temperature is reached, the hot plastic sheet is vacuumed into a temperature-controlled mould. The warm plastic sheet adapts to the moulds contour and is then cooled to below the deformation limit by the temperature control of the mould and the blower, so that the plastic retains the final shape. The result of the thermoforming process is precise and dimensionally stable. The duration of cooling, and also that of heating depends on the thickness of the plastic sheets and the type of plastic on hand.

The use of thermoforming has numerous advantages. With thermoforming the production of smaller quantities is cheaper than with injection moulding or rotational moulding. This is due to the low tooling costs. Thermoforming also produces large batch sizes cost-effectively and quickly and this is a decisive advantage for example over fiberglass, which is also difficult to recycle.

Our plastic products are usually fully recyclable, and we prefer to make products from recycled raw material whenever possible.

Have a glimpse behind Motoseal's scenes and see what thermoforming is basically about.